The house incorporates the latest eco-building techniques with thick sheep wool insulation, breathable hemp lime dry lining and green technology including solar panels and a ground source heat pump. We focussed on developing an air handling system which would monitor air quality in every room and use plants and filters to remove contaminants and purify the air. We also manufactured the bespoke staircase and roof flashings.

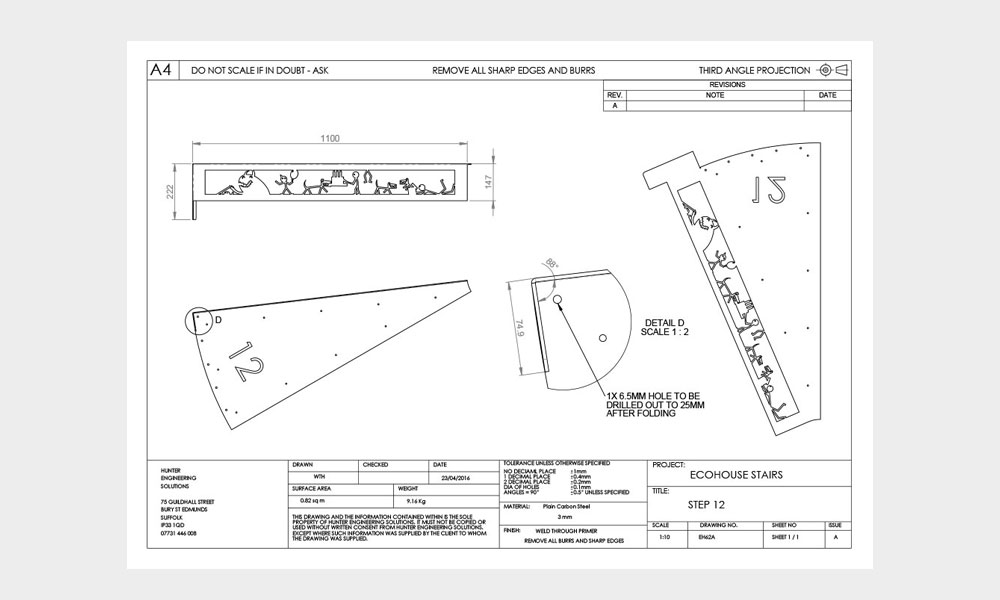

Air Handling

Ductwork was installed in the floors and walls of the house for pumping air in and out of each room. Purified air is supplied into the house through atriums packed with air filtering plants. Hot air is extracted from above the windows in each room, reducing the heating effect caused by the use of glass.

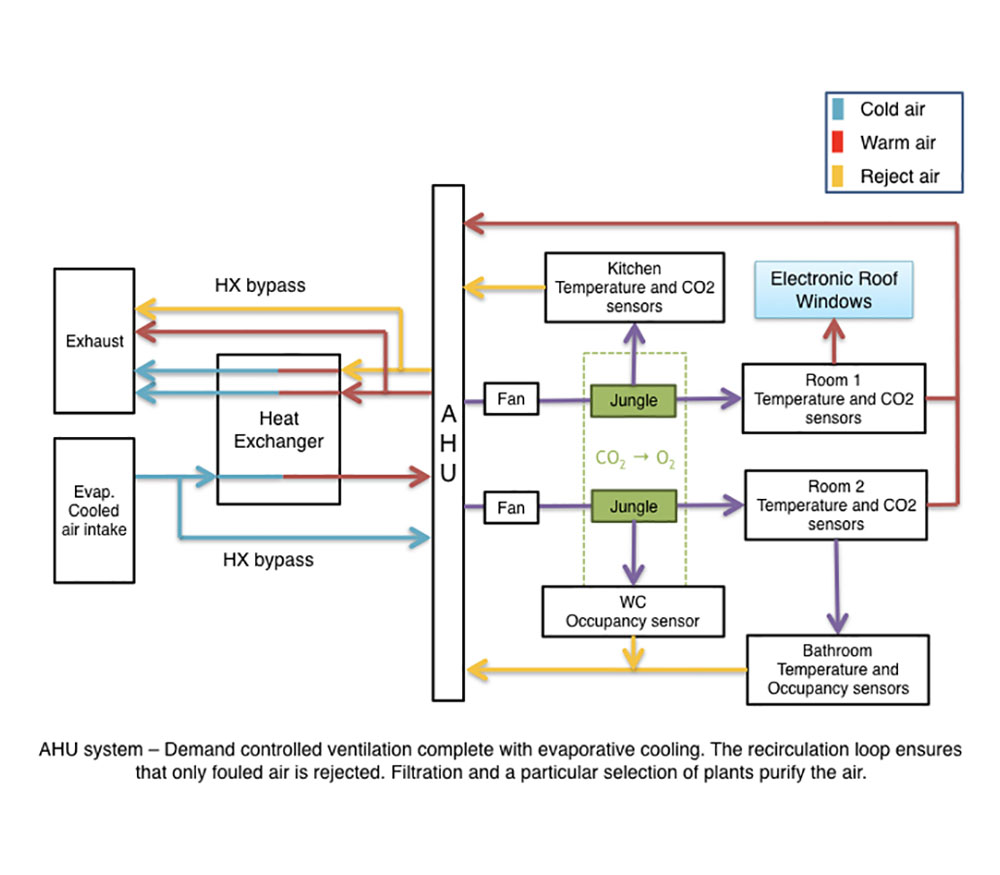

The house is divided into zones and the air handling unit responds to the temperature and CO2 levels, automatically opening windows or activating the cooler as required. The diagram illustrates the function of the system.

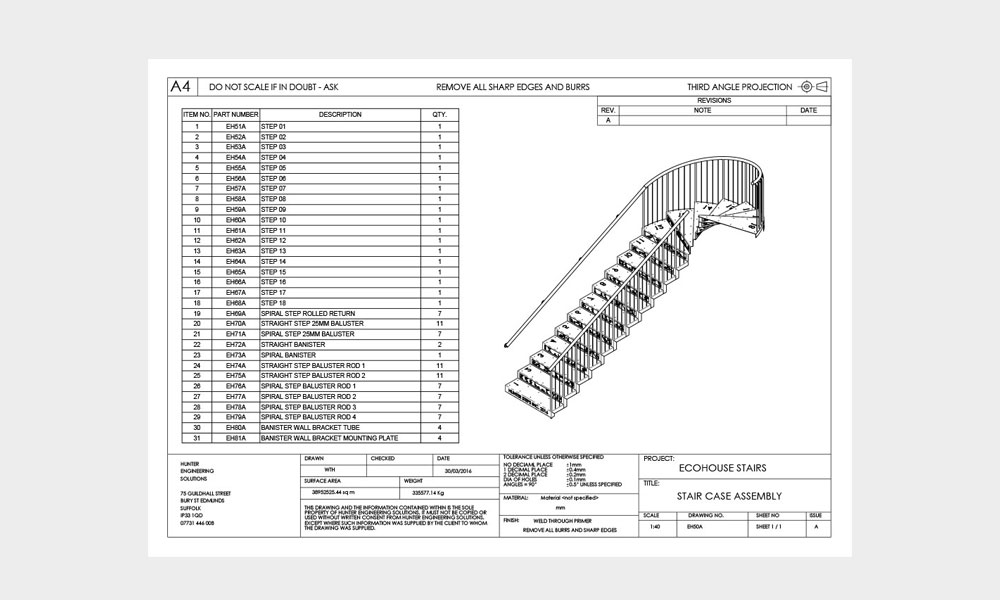

Stairs

Most projects start off with a few pencil sketches…

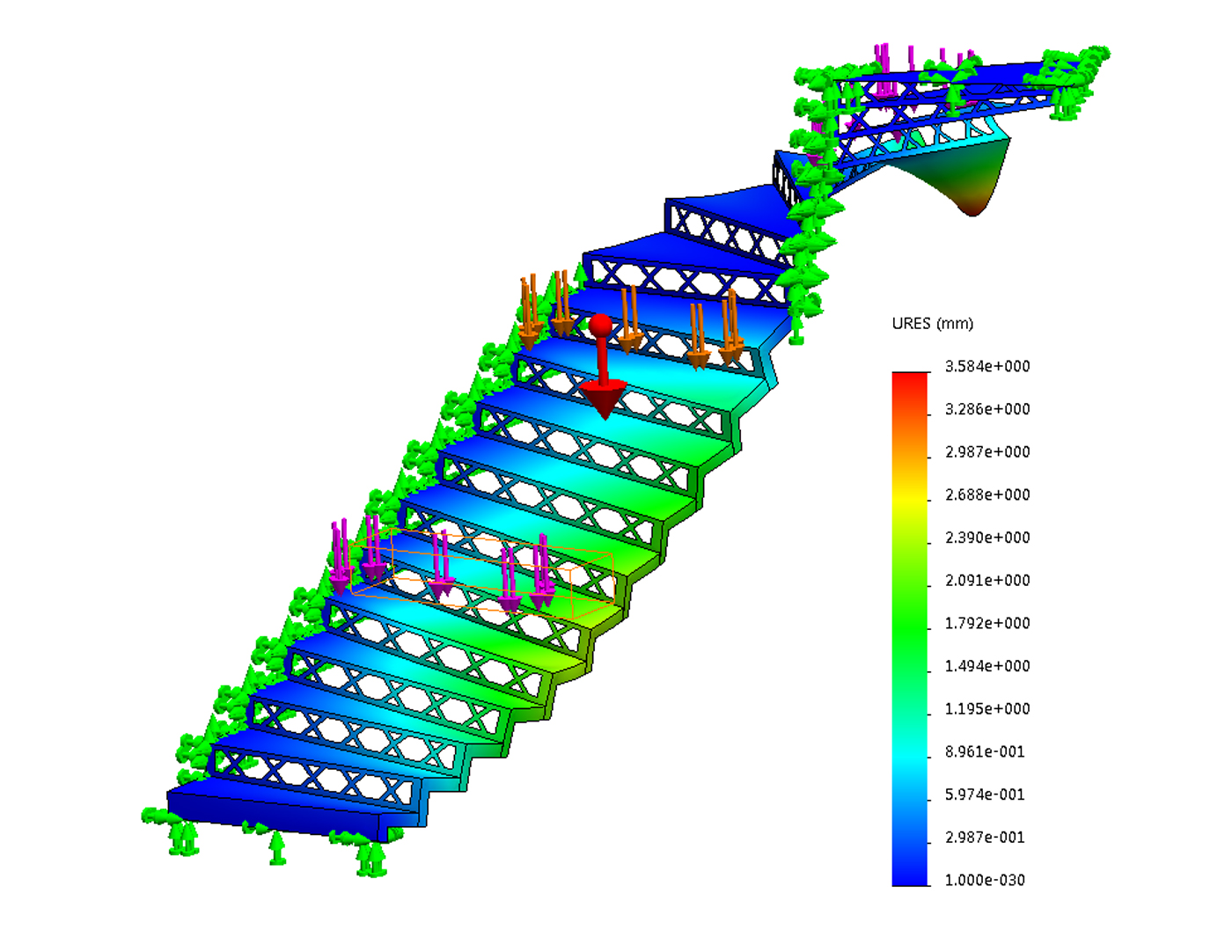

The stairs were designed and modelled on CAD with finite element analysis used to validate the structural integrity.

Each step was individually designed and laser cut from 3mm steel. The spiral handrail was produced by an automated 3D tube bending machine.

All the metal components were welded together on site and coated with clear paint to maintain the weld heat signatures and industrial finish. Finally, oak treads were cut and fitted to each step.