Our challenge was to keep the climbers cool, the café warm and the yogis Zen, also to solve the chalky air quality issue which is largely ignored in climbing centres. As the ambitious project evolved, we ended up taking on more and more.

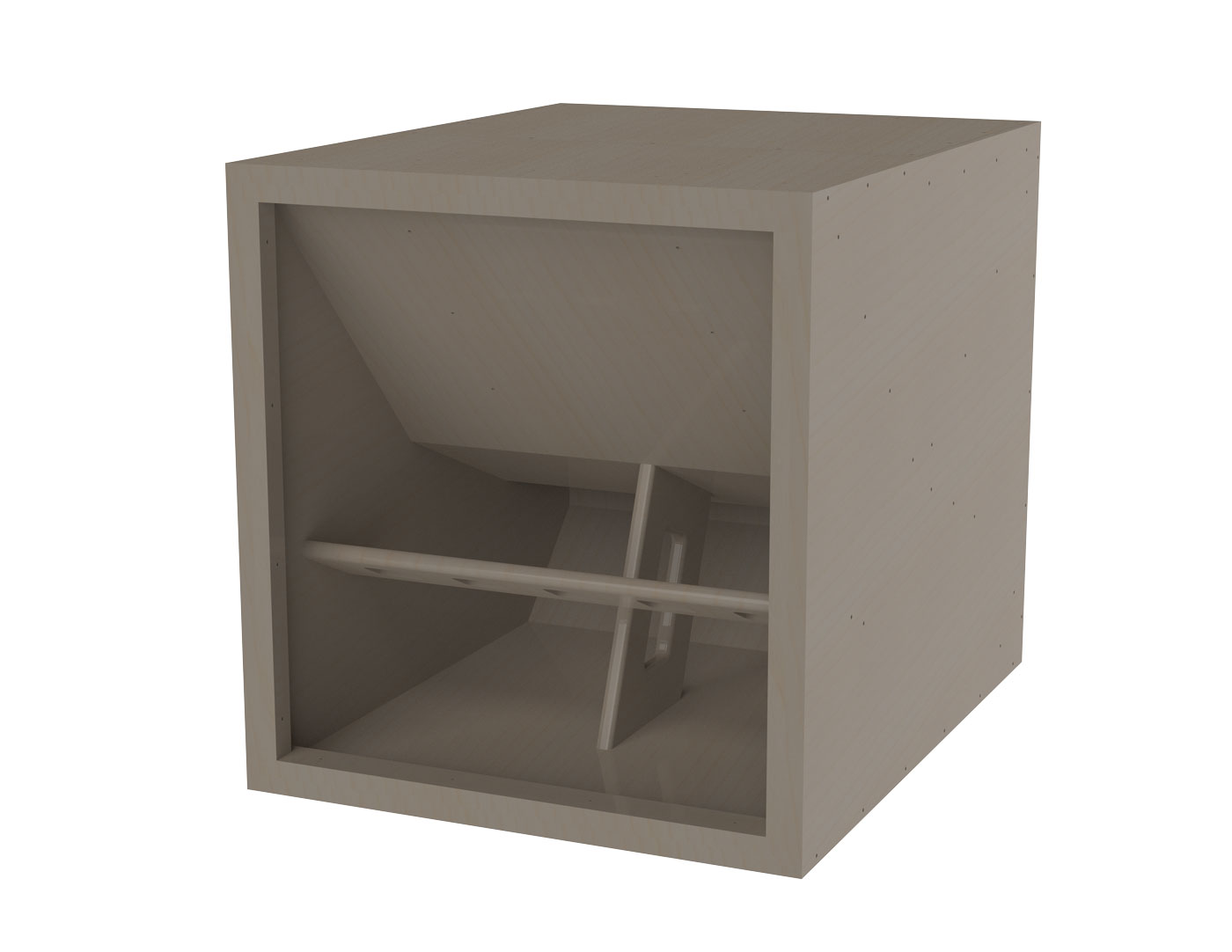

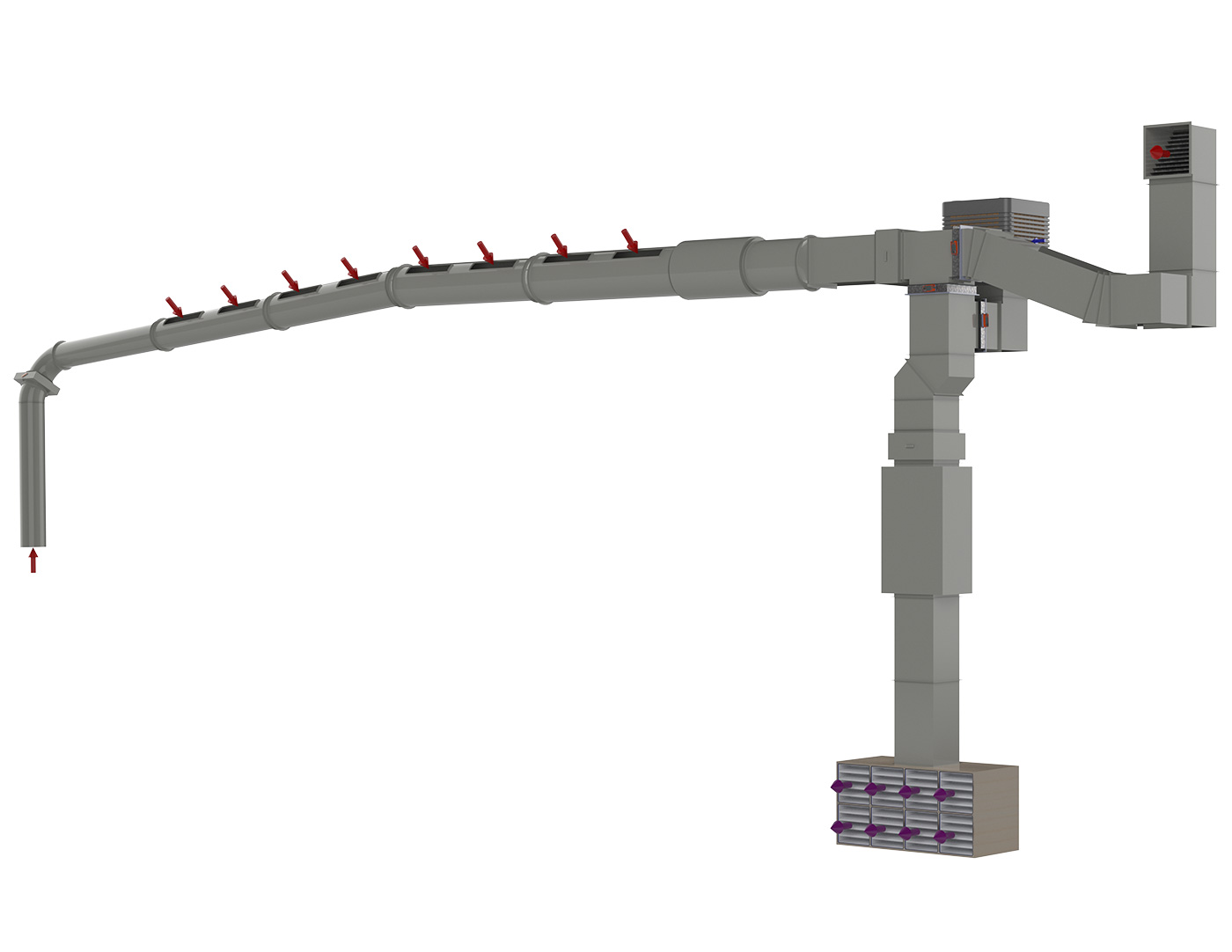

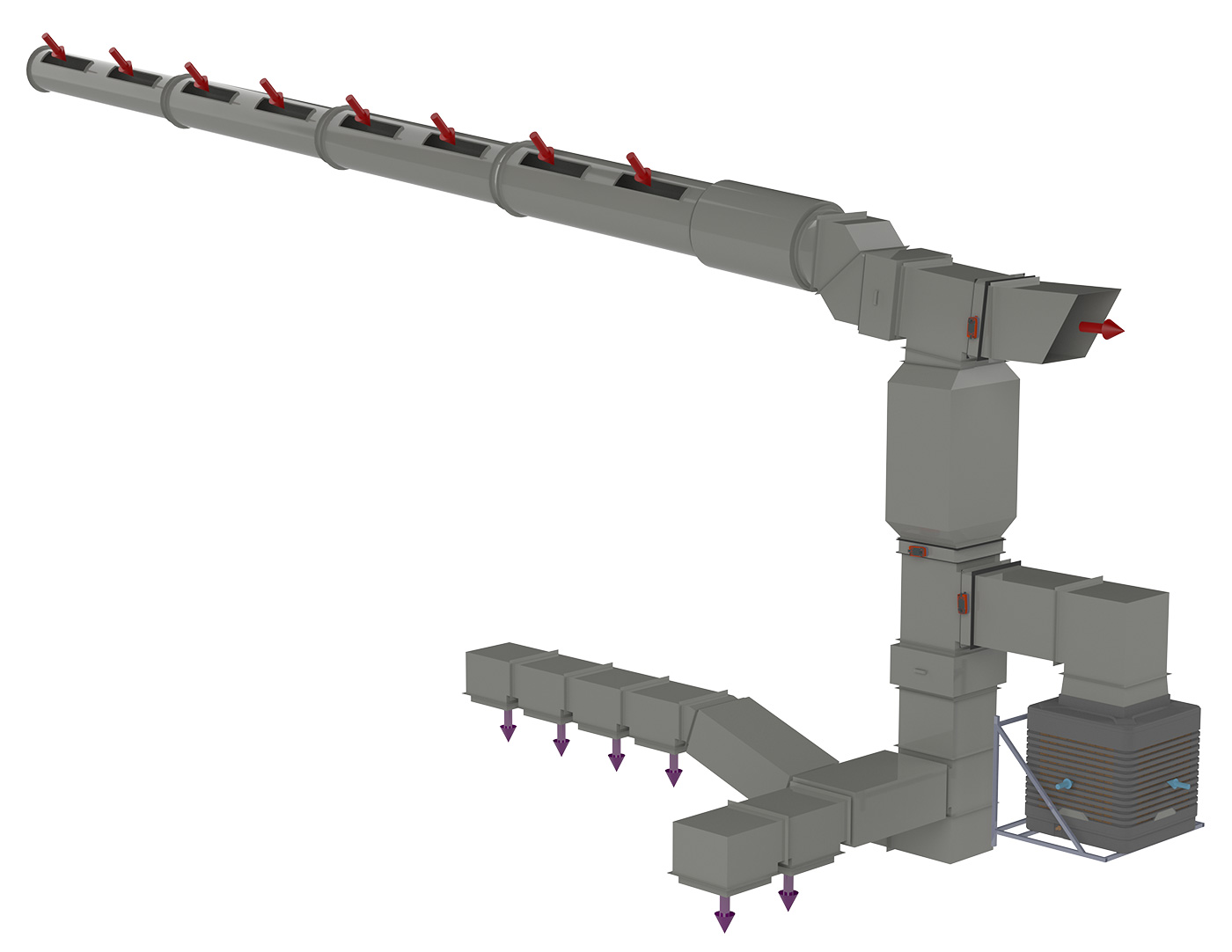

Air Handling Units

Climbers use chalk to improve their grip on the holds, however, much of it ends up in the air and busy centres are often foggy with dust! The key was keeping the chalk suspended in the air where it can be extracted and cleaned by two air handling systems which process up to 36,000m3 of air per hour.

Our old friends at EcoCooling supplied environmentally friendly evaporative cooling units and a control system which regulates temperature and CO2 levels. Hot chalky air is extracted at high level, processed by the air handlers, then supplied at low level through a bank of filters.

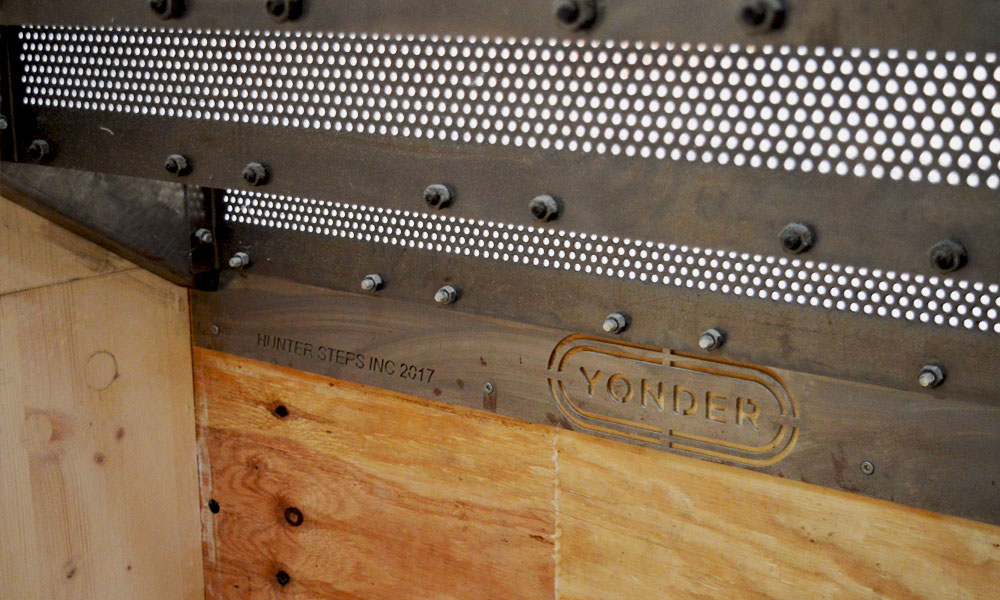

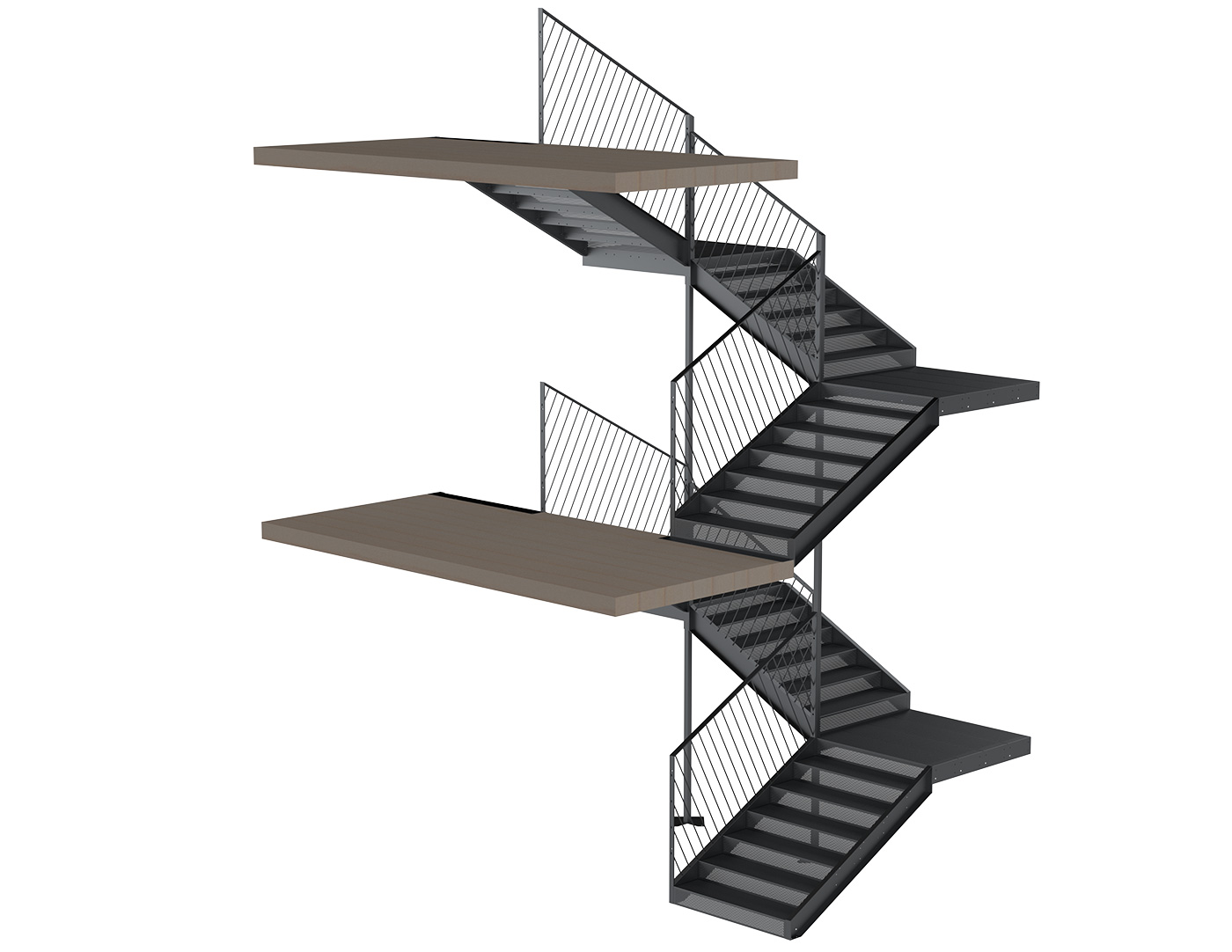

Stairs

As one of the key architectural features of the building, the stairs were intrinsic to the overall design of the centre. Reflecting the look and feel of the staircase, we crafted angled balustrades to line the mezzanines and create a consistent aesthetic throughout.

The perforated steel pattern from the treads was then applied to the lockers and sensor housings to further mirror this style.

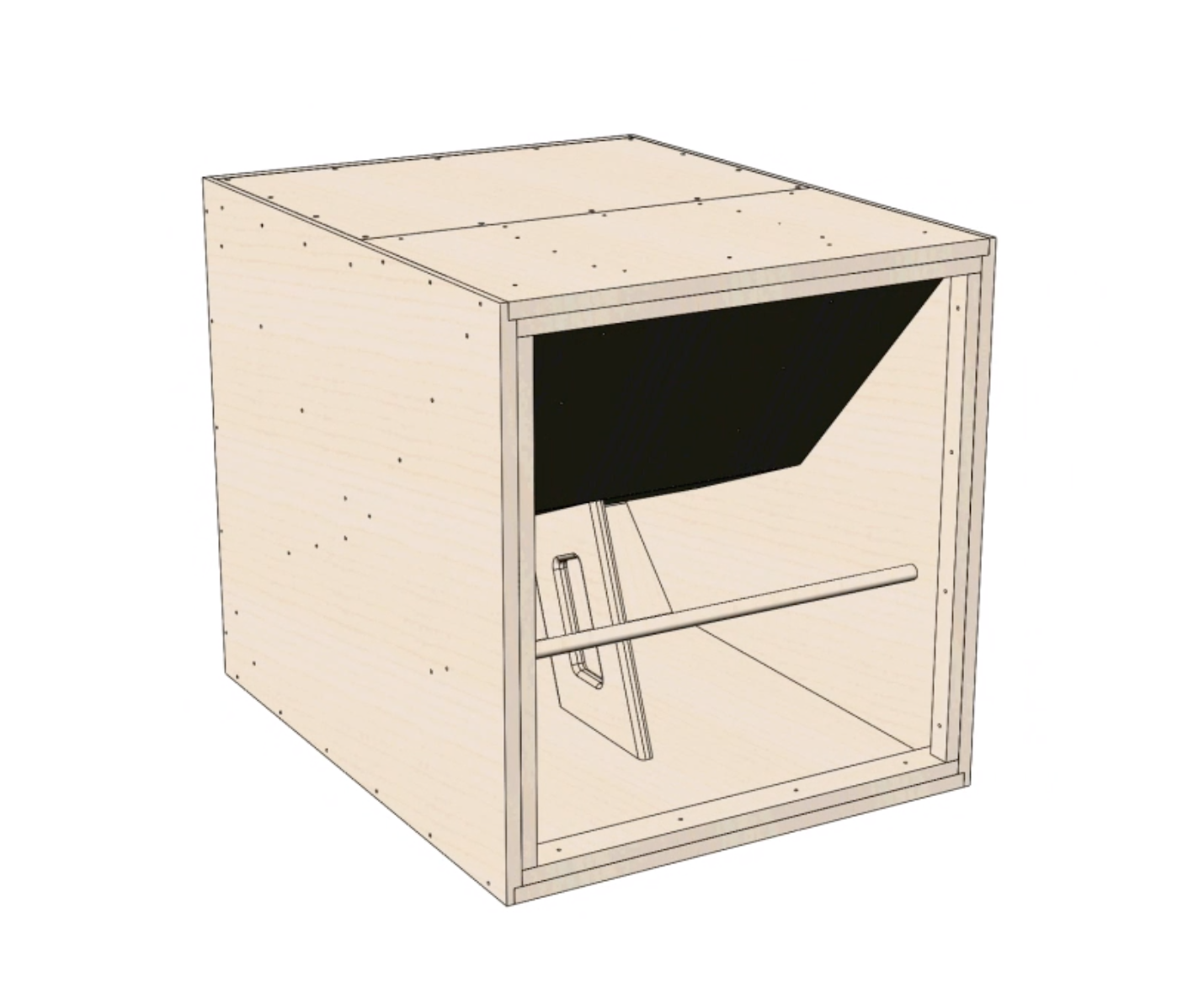

Sound Systems

Yonder was designed to host international climbing competitions so it was important to include a capable sound system. We opted to manufacture these 18” kick bins to match the building’s aesthetic and complement the legendary Turbosound Floodlights.